Copyright © All rights reserved. Made By RT World of Business.

Quality and Autogard are synonymous with overload protection. The company's reputation for high quality products is derived from over 40 years of design innovation and production. Autogard products are manufactured to meet ISO 9001 using the latest machine tools and high

TORQUE LIMITER SERIES 200

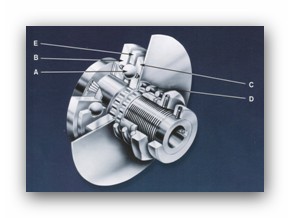

The Series 200 torque limiter is a state of the art mechanical device that will disengage at a pre-set torque value.

The trip torque is set above the normal start-up and operating torque, but below a torque setting which would normally damage the driving and / or driven equipment.

In the event of a jam, the torque limiter eliminates the threat of damage by disconnecting the inertia in the drive train.

Drive balls (A) which are seated in detents in the drive plate and the slide plate (C).

These are all held together under pressure from spring (D).

Disengagement on Overload

When the driven machine either jams or an overload occurs which is greater than the torque setting, the balls roll out of their seats and force apart the drive plate (B) and the slide plate (C).

The balls are retained by the cage plate (E) and roll freely on the flat surface of the drive plate (B) and slide plate (C)

Re-engament

Re-angement occurs in one of three ways depending upon which reset type is selected.

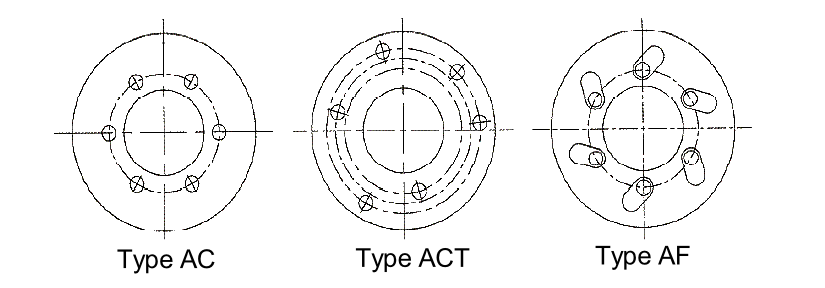

Type AC - Automatic Random Reset

The ball detents in the drive plate (B) and the slide plate (C), as well as the retaining holes in cage plate (E) are equally spaced on the same pitch circle diameter so that the balls will roll into the next detents after tripping in either direction. Immediate shutdown is required to prevent wear of the detents.

Type ACT- Automatic Synchronous Reset

They are positioned in a scattered pattern so that the balls must return to their original position before they can reset.

Re-engagement will occur within two revolutions in other direction. Immediate shutdown is required to prevent wear of the detents

Type AF – Free Wheeling Disengagement

As with the AC the detents in drive plate (B) and slide plate (C) are equally spaced. The retaining holes in the engaging plate (E) are elongated so that as the balls roll from the detents they can follow a cam profile onto a different running track away from the detents. The AF can run at higher speeds as the balls will not ratchet in the detents. Re-setting is achieved by manually locking and reversing the drive

Click to view

Autoflex

Couplings

Samiflex

Elastic

Couplings

Autogard

Series

320

Torque

Limiters

Autogard

Series

400

Torque

Limiters

Autogard

Series

600

Torque

Limiters

Autogard

Series

800

Torque

Limiters