Copyright © All rights reserved. Made By RT World of Business.

|

|

Nominal Torque (kNm) |

Max Torque(KNm) |

Max Speed (1/m in) |

Min Max (Mm) |

DIMENSIONS (mm) |

Mass M |

Moment of Inertia J |

Grease Quantity |

TorsionalStiffnessKx10 | ||||||||

SIZE |

Tk |

Tf |

nk |

d |

D |

C |

A |

Al |

A2 |

E |

f |

G |

H |

[Kg] |

[Kgm2 ] |

[Kg] |

[Nm/rad] |

0 |

1.80 |

4.32 |

6000 |

12-52 |

111 |

43 |

3 |

5 |

7 |

83 |

69 |

39 |

2 |

8 |

0.007 |

0.08 |

4.36 |

1 |

2.76 |

6.62 |

4620 |

18-62 |

142 |

50 |

3 |

8 |

13 |

105 |

85 |

46 |

2 |

13 |

0.018 |

0.09 |

7.31 |

2 |

5.55 |

13.30 |

4140 |

28-78 |

168 |

62 |

3 |

14 |

25 |

131 |

107 |

59 |

2 |

23 |

0.046 |

0.16 |

13.45 |

3 |

8.70 |

20.90 |

4000 |

40-98 |

200 |

76 |

5 |

12 |

19 |

159 |

133 |

69 |

3 |

41 |

0.120 |

0.27 |

24.58 |

4 |

14.10 |

33.80 |

3860 |

50-112 |

225 |

90 |

5 |

24 |

43 |

184 |

152 |

83 |

3 |

60 |

0.229 |

0.47 |

30.34 |

5 |

22.80 |

54.70 |

3720 |

60-132 |

265 |

105 |

6 |

27 |

48 |

212 |

178 |

93 |

3 |

91 |

0.501 |

0.68 |

47.68 |

6 |

34.80 |

83.50 |

3190 |

70-156 |

300 |

120 |

6 |

32 |

58 |

246 |

209 |

106 |

3 |

141 |

1.005 |

0.93 |

68.27 |

7 |

44.00 |

105.60 |

2900 |

85-174 |

330 |

135 |

8 |

37 |

66 |

275 |

234 |

118 |

4 |

199 |

1.734 |

1.54 |

97.85 |

8 |

69.80 |

167.60 |

2570 |

95-190 |

370 |

150 |

8 |

50 |

92 |

307 |

254 |

138 |

4 |

285 |

3.029 |

2.28 |

136.10 |

9 |

83.80 |

201.10 |

2330 |

110-210 |

406 |

175 |

8 |

53 |

98 |

335 |

279 |

154 |

4 |

352 |

4.556 |

3.10 |

159.90 |

10 |

152.00 |

364.80 |

2150 |

120-233 |

438 |

190 |

8 |

58 |

108 |

367 |

305 |

166 |

4 |

428 |

6.165 |

3.90 |

203.30 |

11 |

203.50 |

488.40 |

1800 |

130-280 |

505 |

220 |

10 |

72 |

134 |

423 |

355 |

193 |

5 |

596 |

12.550 |

6.20 |

283.00 |

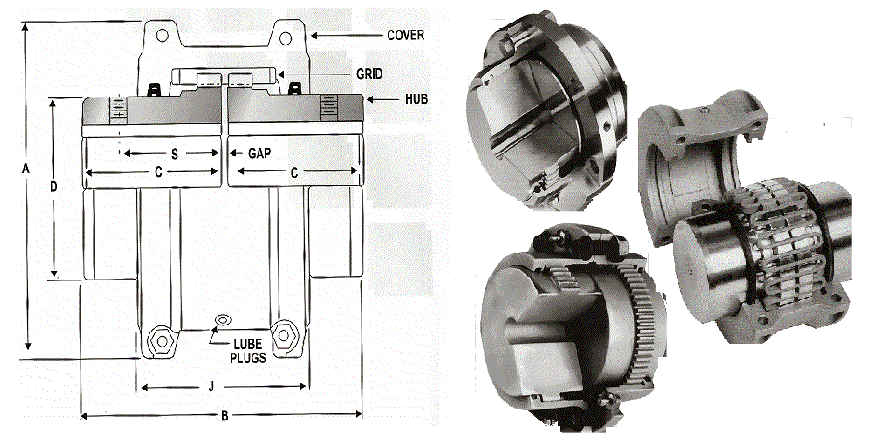

CPLG. |

CPLG. |

MAX |

MIN |

(2) |

(1) |

(1) |

A |

B |

C |

D |

J |

GAP |

S |

SIZE |

RATING |

RPM |

BORE |

MAX |

WT |

WK2 |

|

|

|

|

|

|

|

|

|

Nm |

|

mm |

BORE mm |

kg |

Kgm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1020TG |

48 |

4500 |

13 |

27 |

1.80 |

0.0014 |

102.0 |

98.0 |

47.5 |

39.7 |

66.7 |

3.2 |

35 |

1030TG |

136 |

4500 |

13 |

35 |

2.40 |

0.0022 |

111.0 |

98.0 |

47.5 |

49.2 |

68.3 |

3.2 |

40 |

1040TG |

226 |

4500 |

13 |

44 |

3.20 |

0.0330 |

118.0 |

105.0 |

50.8 |

57.2 |

69.9 |

3.2 |

40 |

1050TG |

395 |

4500 |

13 |

51 |

5.20 |

0.0073 |

138.0 |

124.0 |

60.3 |

66.7 |

79.4 |

3.2 |

45 |

1060TG |

621 |

4350 |

19 |

57 |

7.10 |

0.0119 |

151.0 |

130.0 |

63.5 |

76.2 |

92.0 |

3.2 |

53 |

1070TG |

904 |

4125 |

19 |

68 |

10.10 |

0.0185 |

162.0 |

156.0 |

76.2 |

87.3 |

95.3 |

3.2 |

54 |

1080TG |

1864 |

3600 |

25 |

83 |

17.70 |

0.0451 |

194.0 |

181.0 |

88.9 |

104.8 |

115.9 |

3.2 |

65 |

1090TG |

3390 |

3600 |

25 |

95 |

24.50 |

0.0787 |

213.0 |

200.0 |

98.4 |

123.8 |

122.2 |

3.2 |

72 |

1100TG |

5706 |

2440 |

42 |

108 |

41.30 |

0.1782 |

251.0 |

246.0 |

120.6 |

142.1 |

155.6 |

4.8 |

- |

1110TG |

8475 |

2250 |

42 |

117 |

53.60 |

0.2701 |

270.0 |

259.0 |

127.0 |

160.4 |

162.6 |

4.8 |

- |

1120TG |

12428 |

2025 |

60 |

137 |

78.70 |

0.5136 |

308.0 |

305.0 |

149.2 |

179.4 |

192.0 |

6.4 |

- |

1130TG |

18078 |

1800 |

66 |

165 |

118.00 |

0.9885 |

347.0 |

330.0 |

161.9 |

217.5 |

195.2 |

6.4 |

- |

1140TG |

25987 |

1650 |

66 |

184 |

176.00 |

1.8454 |

384.0 |

375.0 |

182.8 |

254.0 |

201.5 |

6.4 |

- |

1150TG |

36130 |

1500 |

108 |

203 |

227.00 |

- |

453.0 |

372.0 |

182.8 |

269.0 |

271.2 |

6.4 |

- |

1160TG |

50810 |

1350 |

120 |

228 |

307.00 |

- |

501.0 |

402.0 |

198.1 |

304.8 |

278.9 |

6.4 |

- |

1170TG |

67740 |

1225 |

133 |

254 |

434.00 |

- |

566.0 |

438.0 |

215.9 |

355.6 |

304.3 |

6.4 |

- |

1180TG |

93930 |

1100 |

152 |

279 |

600.00 |

- |

629.0 |

483.0 |

238.7 |

393.7 |

321.0 |

6.4 |

- |

1190TG |

124000 |

1050 |

- |

335 |

4.40 |

- |

675.6 |

524.2 |

259.1 |

436.9 |

325.1 |

6.0 |

- |

1200TG |

169000 |

900 |

- |

360 |

5.62 |

- |

756.9 |

564.8 |

279.4 |

497.8 |

355.6 |

6.0 |

- |

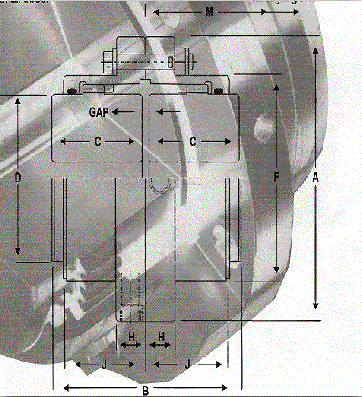

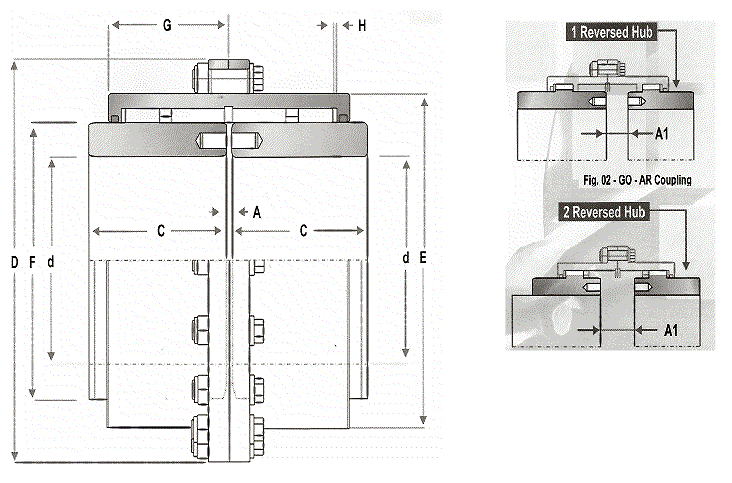

GO _ A , GO-AR & GO-ARR Couplings

DENOMINATION EXAMPLE: GO-A GEAR COUPLING SIZE 6 TAB.11

DOUBLE ENGAGEMENT COUPLINGS FOR HORIZONTAL SHAFTS

The standard range of gear couplings will accommodate parallel offset, angular misalignment & axial movement, or a combination of all three.

Operating Misalignment | ||

Size |

Parallel |

Angular |

10 |

0.005 |

0.005 |

15 |

0.005 |

0.005 |

20 |

0.010 |

0.010 |

25 |

0.010 |

0.010 |

30 |

0.012 |

0.015 |

35 |

0.012 |

0.015 |

40 |

0.012 |

0.020 |

45 |

0.012 |

0.020 |

50 |

0.012 |

0.020 |

55 |

0.012 |

30.000 |

60 |

0.012 |

0.030 |

70 |

0.012 |

0.030 |

CouplingRating |

MAXSPEEDRPM(1) |

Bore DiaMm(2) |

Dimensions in mm (3) |

|

| |||||||||||

SIZE |

kW/r pm |

kNm |

MAX |

MIN |

A |

B |

(5)C |

D |

F |

H |

J |

M |

GAP |

(6)Masskg |

Mr2InertiaKm2 | |

10 |

0.125 |

1.2 |

8000 |

52 |

16 |

116 |

89 |

43 |

69 |

84 |

14 |

39 |

51 |

3.00 |

4.37 |

0.005 |

15 |

0.261 |

2.5 |

6500 |

65 |

24 |

152 |

102 |

50 |

86 |

105 |

19 |

48 |

61 |

3.00 |

8.96 |

0.019 |

20 |

0.521 |

5.0 |

5600 |

80 |

28 |

178 |

127 |

62 |

105 |

127 |

19 |

60 |

76 |

3.00 |

14.8 |

0.041 |

25 |

0.907 |

8.7 |

5000 |

98 |

35 |

213 |

159 |

77 |

131 |

155 |

22 |

72 |

92 |

5.00 |

26.4 |

0.105 |

30 |

1.344 |

12.9 |

4400 |

115 |

42 |

240 |

187 |

91 |

152 |

181 |

22 |

84 |

106 |

5.00 |

39.6 |

0.195 |

35 |

2.022 |

19,4 |

3900 |

135 |

50 |

279 |

219 |

107 |

178 |

211 |

29 |

98 |

130 |

6 |

65 |

0.454 |

40 |

3.179 |

30.5 |

3600 |

160 |

50 |

316 |

247 |

121 |

210 |

246 |

29 |

111 |

145 |

6.00 |

96.0 |

0.860 |

45 |

4.356 |

41.8 |

3200 |

180 |

55 |

346 |

278 |

135 |

235 |

274 |

29 |

123 |

165 |

8.00 |

131.0 |

1.390 |

50 |

5.940 |

57.0 |

2900 |

195 |

75 |

389 |

314 |

153 |

254 |

306 |

38 |

141 |

183 |

8.00 |

186.0 |

2.530 |

55 |

8.441 |

81.0 |

2650 |

215 |

75 |

425 |

344 |

168 |

279 |

334 |

38 |

158 |

203 |

8.00 |

247.0 |

3,83 |

60 |

9.990 |

95.0 |

2450 |

235 |

80 |

457 |

384 |

188 |

305 |

366 |

26 |

169 |

228 |

8.00 |

299.0 |

5.210 |

70 |

15.310 |

147.0 |

2150 |

280 |

100 |

527 |

451 |

221 |

356 |

425 |

29 |

196 |

266 |

10.00 |

473.0 |

11.000 |

- The maximum speeds specified above are generally based on the limit of the lubricant being used. To attain these speeds a separate balance operation may be necessary depending on the requirements of the application. Special couplings can be supplied for higher speeds or more sensitive applications

- Maximum bores specified are for uniformly loaded drives only.

- All dimensions are subject to confirmation. General arrangement drawings are available which show certified dimensions.