Copyright © All rights reserved. Made By RT World of Business.

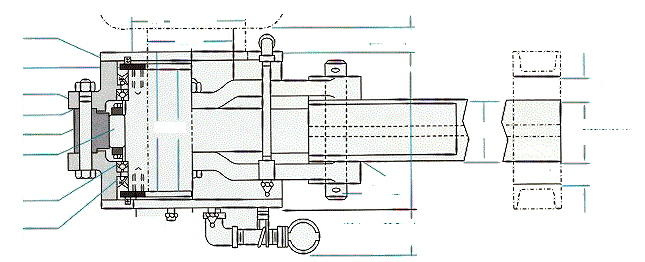

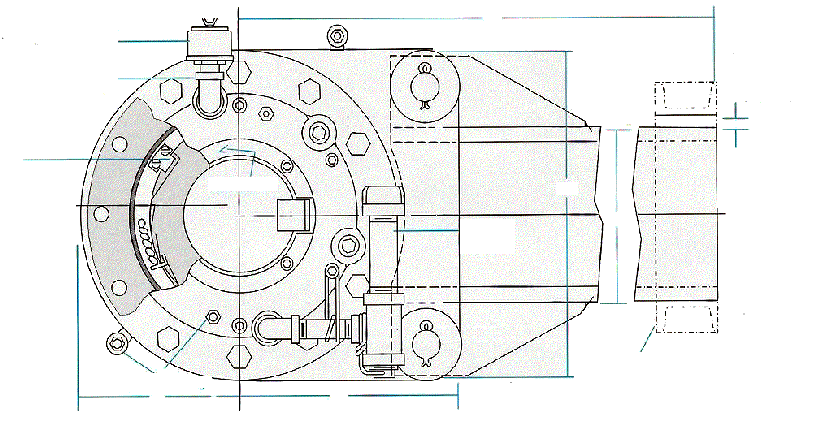

The torque arm end must not be rigidly attached to steel framework. The bracket or stirrup of the end of the torque arm must provide clearance to permit the Anti Runback to center itself in axial and angular positions to prevent pincing of bearings and damage or failure of unit, and must be sufficient for "L" loads above and below torque arm for Anti Runback size selected. The preferred position is horizontal to reduce bearing loading for longer bearing life. Refer to certified drawings and instruction bulletins furnished with each other.

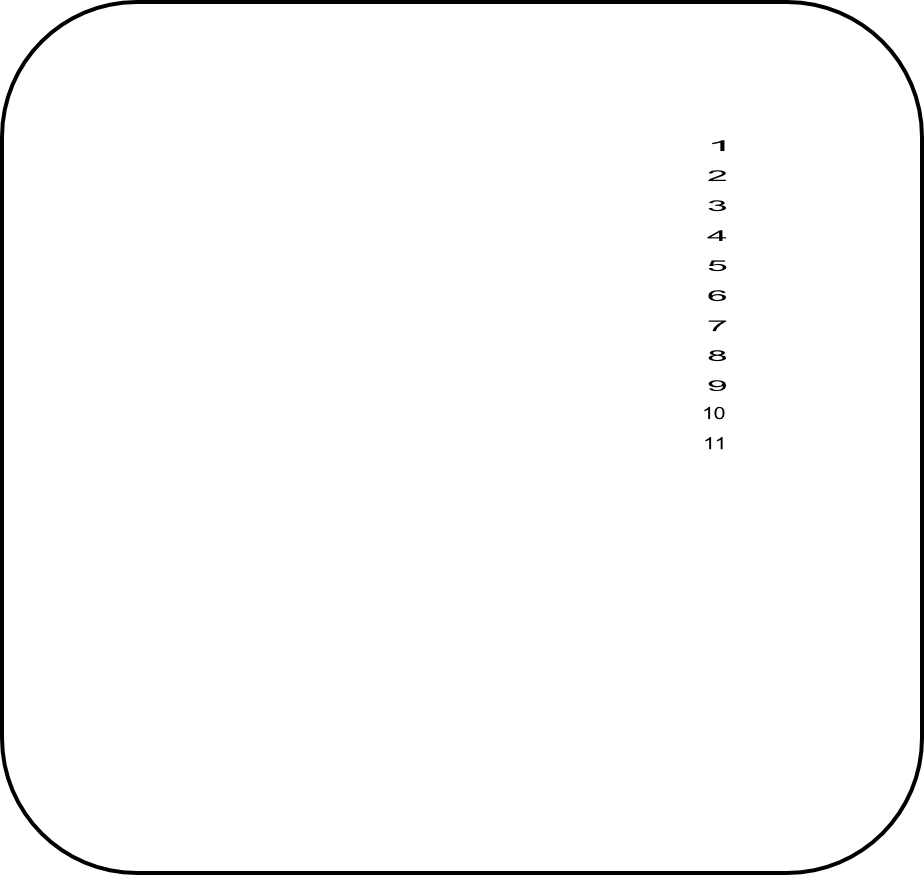

Cover plate

Gasket

Ball Bearing

Oil Seal

Outer Race

Sprag Cage

Pin & Cotter Keys

Torque Arm

Stop Lug

Doublelip Seal er

Outer Labyrinth

11

10

1

2

5

6

3

4

k

Clearance

dia

Bore

H

C

Pull-of

Holes

Holes

38.1 mm -63 mm

Clearance on all units

Clearance on all units

24.5mm

Clearance on all units

Clearance on all units

38.1 mm

Clearance for

actual positioning

actual positioning

38.1 mm

Breather

Filter

Filter

Oil fill

Fitting

Fitting

9

See note 14

Grease Relief Fittings

J

B

Stirrip for end of Torque arm

By Customer.

Make brackets above and

Below Torque Arm

Sufficient for “L” Loads

By Customer.

Make brackets above and

Below Torque Arm

Sufficient for “L” Loads

Oil Level

Indicator

Indicator

G

A

E

6.35 mm

Min Clearance

To Permit

Backstop to center

Itself when

freewheeling

To Permit

Backstop to center

Itself when

freewheeling

See note 14

D

7

8

VAR3SC |

3818 |

7637 |

300 |

510 |

75 |

20 x 4.9 |

46 |

VAR6SC |

7600 |

15200 |

250 |

920 |

95 |

25 x 5.4 |

69 |

VAR12SC |

15000 |

30000 |

210 |

1325 |

120 |

32 x 7.4 |

100 |

VAR18SC |

25500 |

51000 |

180 |

1776 |

140 |

36 x 8.4 |

152 |

VAR27SC |

39000 |

78000 |

150 |

2259 |

165 |

40 x 9.4 |

207 |

VAR63SC |

44500 |

89000 |

120 |

4452 |

205 |

50 x 11.4 |

381 |

VAR90SC |

77800 |

155600 |

105 |

6072 |

240 |

56 x 12.4 |

520 |

VAR135SC |

81500 |

163000 |

90 |

8464 |

265 |

63 x 12.4 |

690 |

VAR186SC |

142625 |

285250 |

80 |

10580 |

300 |

70 x 14.4 |

966 |

Max Torque

NM

Max

RPM

Load

“L”

Kgs

Max

Bore

mm

Max bore

Key way

mm

Nominal Torque

NM

Backstop

Size

Ship weight

kg's

VAR3SC |

210 |

143 |

105 |

64 |

76 |

133 |

813 |

119 |

105 |

88 |

VAR6SC |

248 |

165 |

127 |

70 |

102 |

159 |

914 |

143 |

124 |

108 |

VAR12SC |

292 |

203 |

133 |

83 |

127 |

165 |

1270 |

149 |

146 |

133 |

VAR18SC |

343 |

235 |

148 |

92 |

152 |

179 |

1422 |

164 |

168 |

162 |

VAR27SC |

384 |

254 |

178 |

98 |

178 |

213 |

1676 |

195 |

191 |

181 |

VAR63SC |

498 |

311 |

203 |

127 |

254 |

238 |

1981 |

221 |

244 |

241 |

VAR90SC |

584 |

362 |

229 |

140 |

305 |

267 |

2083 |

248 |

270 |

270 |

VAR135SC |

654 |

406 |

254 |

143 |

381 |

298 |

2235 |

276 |

308 |

324 |

VAR180SC |

774 |

419 |

273 |

159 |

457 |

321 |

2388 |

297 |

349 |

362 |

Backstop

Size

A

mm

J

mm

H

mm

G

mm

F

mm

E

mm

D

mm

C

mm

B

mm

K

mm

The holdback oil must be drained and flushed out, preferably whilst unit is operating, to flush properly. |

The holdback must be refilled with an oil viscosity grade of 100. |

The grease dust plug must be removed and all the old grease must be pumped out to remove the dust from the system. |

Do not pump any grease in unless the plugs are removed it will cause holdback failure. |

Oil samples must be analyzed to check for material particles. |

Damaged grease nipples must be replaced |

Damaged pipe leaks must be sealed or replaced. |

The inspection must be completed like the weekly inspection and then be serviced as follows

Check all pipe work |

If leaking - repair |

Check oil level sight glass |

If cracked - replace |

Check breather |

If elements is blocked - replace. If cover is damaged - replace. |

Check oil level |

If low-top up |

Check torque arm pins |

If split pins are missing - Fit new split pins |

Check holdback temperature |

If more that the ambient temp. Plus 200 degrees call.Quesco for assistance (930 C Max with ambient of 520 C) |

Check vibration sensor |

If any vibration other that the installation vibration is present callQuesco immediately to assist you. |

Check The torque arm support stirrup |

If loose, or any bolts missing replace or repair immediately, the torque arm sideclearance must not be less that 25 mm both sides of the torque arm. |

Check grease in purging cavity |

Pump grease in at every inspection, this is only to keep the dust out(Remove the dust plug before pumping the grease in) any EP 2 or normalGrease can be used. |

NOTE:

A Backstop be mounted for desired rotation. Arrow on inner race indicates direction of free shaft rotation.

Before mounting on shaft, be sure to check direction of free rotation.

NOTE

N Seals are factory packed with grease.

Before placing in operation, backstop must be filled internally with recommended oil.

Weekly Inspection

3Monthly Inspection and Service

Engineering Data

Dimensions and Data

Anti-Runbacks