Copyright © All rights reserved. Made By RT World of Business.

Conductor Bar |

Galvanised steel |

Copper |

Aluminium / Stainless steel | |||||

Nominal current |

60A |

100A |

125A |

160A |

250A |

400A |

200A |

315A |

Cross sectional area |

50mm |

63mm |

93mm |

50mm |

63mm |

93mm |

104mm |

120mm |

Maximum system voltage |

|

|

|

|

|

|

|

|

(AC)(contact us for other voltages ) |

1000v |

1000V |

1000v |

1000v |

1000v |

1000v |

1000v |

1000v |

( DC )(contact us for other voltages ) |

1000v |

1000V |

1000v |

1000v |

1000v |

1000v |

1000v |

1000v |

Resistance R (for DC) at20 0 c ohm/m |

0.003584 |

0.002867 |

0.001933 |

0.000342 |

0.000274 |

0.000184 |

0.000301 |

0.000288 |

Impedance Z (for AC) at 20�C ohm./m |

0.003604 |

0.002891 |

0.001968 |

0.000364 |

0.0003 |

0.000221 |

0.000325 |

0.000288 |

Maximum allowable ambient Temperature for 100% duty cycle |

25°C |

25 °C |

25°C |

25°C |

25°C |

25°C |

25°C |

25°C |

Bar length |

4.5m |

4.5m |

4.5m |

4.5m |

4.5m |

4.5m |

4.5m |

4.5m |

Support pitch Standard |

1500mm |

1500mm |

1500mm |

1500mm |

1500mm |

1500mm |

1500mm |

1500mm |

Lateral |

1125mm |

1125mm |

1125mm |

1125mm |

1125mm |

1125mm |

1125mm |

1125mm |

Minimum pitch centres |

|

|

|

|

|

|

|

|

Standard |

43mm |

43mm |

43mm |

43mm |

43mm |

43mm |

43mm |

43mm |

Insulated |

60mm |

60mm |

60mm |

60mm |

60mm |

60mm |

60mm |

60mm |

Expansion sections: not required for runs less than |

150m |

150m |

150m |

150m |

150m |

150m |

150m |

150m |

Minimum bending radius: (horizontal only) |

1.5m |

1.5m |

1.5m |

1.5m |

1.5m |

1.5m |

1.5m |

1.5m |

TECHNICAL DATA | ||||||||

Safe-lee protected conductor bars meet the demands of the following international safety standards. | ||||||||

NFC 20-010, NFC 63-010, NFC 32-070, VIDE 0470, BS EN 60529, DIN 53438. | ||||||||

|

|

|

|

|

|

|

|

|

|

Conductor Bar Cover |

Standard |

Medium Heat |

Maximum allowable temperature in relation to duty cycle | |||||

Material |

PVC |

BAYBLEND | ||||||

Dielectric strength |

180 KV/cm |

240 KV/cm | ||||||

Surface resistivity |

10 (ohm) |

10 ohm | ||||||

Volume resistivity |

10 5215(ohm)/cm |

10 ohm/cm |

Duty cycle |

100 % |

80% |

60% |

40% |

20% |

Vicat softening temperature |

84°C |

120°C |

Maximum allowable ambient temperature with standard insulating cover |

25°C |

30°C |

35°C |

40°C |

55°C |

(Never expose PVC cover |

|

| ||||||

to temperatures in excess |

|

| ||||||

of 80`C) |

|

| ||||||

Flame-test |

54% |

24% | ||||||

Oxygen index |

Self extinguishing |

Self extinguishing | ||||||

Specific density |

1.5 .cm |

1.15 .cm | ||||||

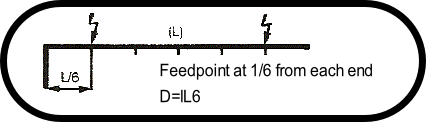

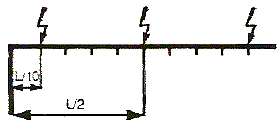

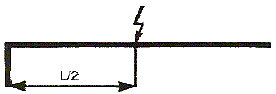

Three feedpoints at L/2 and L/10

From each end

D= L/10

U% = x100%

ohm U = Volt drop in volts

I = Maximum current in Amps

D = Distance between the feed and pick-up points in meters

R = Resistance of conductor in ohms per meter

ohm U = 3 x I x D x Z

ohm U = 2 x I x D x Z

ohm U = 2 x I x D x R

Conductor Rails - Technical Data

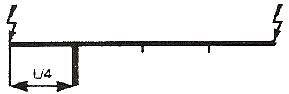

End feed

D=L

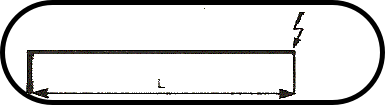

Centre feed

D = L/2

Feedpoint ateach end

D= L/4