FLUID DRIVE COUPLINGS

Constant Filling

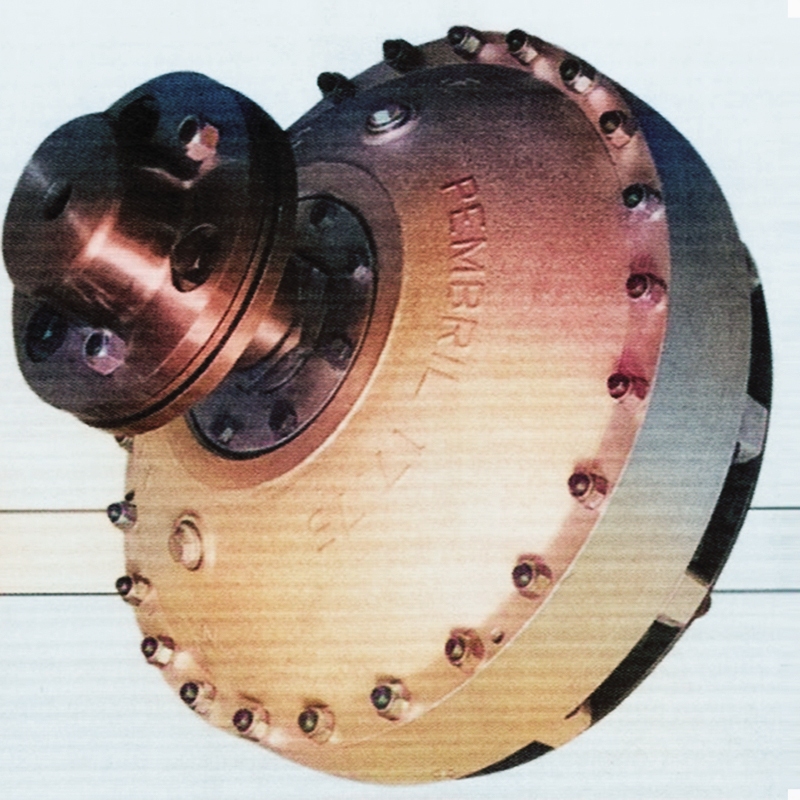

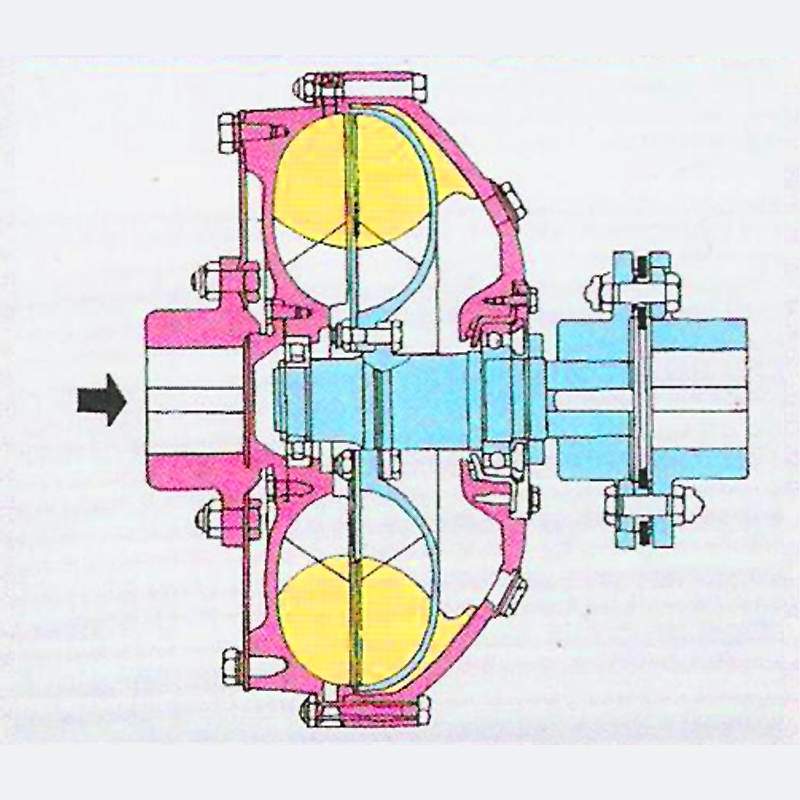

The type FCU fluid coupling when used in conjunction with a fixed-speed motor

will give the motor a light-load start, provide smooth acceleration and ensure overload protection for the motor and driven machine. Using a fluid coupling in the drive line often makes it possible to employ a smaller motor, because the fluid coupling will allow the motor to run quickly up to speed, where its overload capacity may be used for starting the machine.

Starting or stalling torque may be determined precisely by the selection of the initial oil filling. Further adjustments, to suit drive requirements, may easily be made at the site. The type FCU fluid coupling is a compact, rugged unit, the major components being aluminium alloy castings. It comprises the basic fluid coupling, diaphragm input mounting and multidisc-type semi-flexible coupling on the output side. Bores and keyways may be finished to suit customer's requirements.

Fusible plugs are fitted to all except the smaller model fluid couplings to provide protection against excess temperature rise should the motor overload trip fail to operate during stall or overload conditions. Vertical applications can be catered for in most sizes.

Units are available in sixteen sizes, covering ratings from 0.1 kW to 1000kW.

SOME OF THE TYPICAL APPLICATIONS INCLUDE:

-

Belt Conveyors

-

Barking Drums

-

Ball Mills

-

Rotary Dryers

-

Reciprocating Pumps

-

Crushers

-

Winches

-

Centrifuges

-

Chain Conveyors

-

Cranes

-

Hammer Mills

-

Haulages

-

Mixers and Agitators

-

Marine Transmission

Thechnical Data

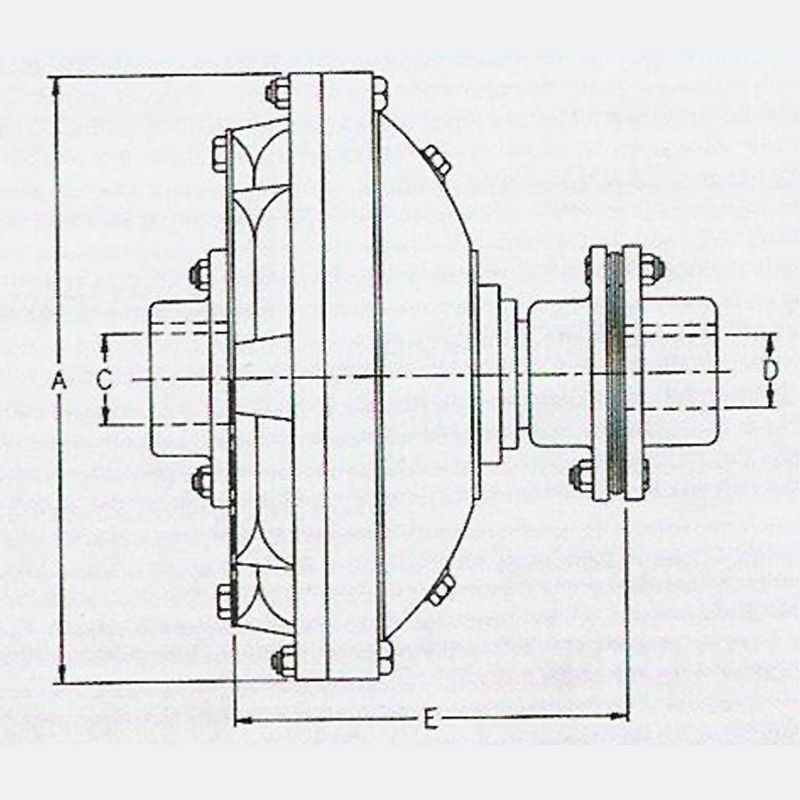

Size | A | C | D | E | Filed Weight (kgs) | GD2-PRI | Oil Qty Ltr. |

(Kg m2) | |||||||

8 | 237 | 42 | 35 | 165 | 13.2 | 0.246 | 1.7 |

9.25 | 268 | 48 | 48 | 194 | 17.7 | 0.332 | 2.6 |

10.5 | 308 | 48 | 48 | 210 | 22.2 | 0.54 | 3.7 |

11.5 | 333 | 60 | 55 | 232 | 35 | 0.75 | 4.6 |

12.75 | 368 | 60 | 55 | 262 | 41 | 1.38 | 6.8 |

14.5 | 419 | 80 | 70 | 287 | 57.6 | 2.53 | 10.2 |

16.25 | 454 | 80 | 70 | 335 | 74 | 4.2 | 13.6 |

17.75 | 502 | 85 | 76 | 354 | 106 | 6.4 | 17 |

20 | 578 | 85 | 76 | 390 | 142 | 11.5 | 26 |

23 | 660 | 110 | 100 | 457 | 207 | 23 | 40 |

26 | 749 | 110 | 100 | 492 | 0.27 | 38 | 57 |

29 | 838 | 130 | 115 | 552 | 358 | 65 | 78 |

32 | 914 | 150 | 115 | 587 | 520 | 95 | 106 |

36 | 1032 | 150 | 150 | 626 | 678 | 182 | 136 |

41 | 1162 | 150 | 150 | 660 | 948 | 316 | 205 |

TYPE FCU SELECTION TABLE

The chart maybe used for selecting a type FCU fluid coupling. It shows maximum operating power ratings for approved application with direct-on started squirrel cage motors, and will allow 200% full load torque for starting. Selections may be different from those shown, for drives having frequent cyclic duty, very high inertia starting, or diesel engine drives, such cases should be referred to Premium Energy Transmission Ltd. Office or representative who will prepare specific proposals.

These ratings are also generally suitable for drives employing slip-ring motors; for drives using DC motors consult Premium Energy Transmission Ltd. Allow for 3 to 5% slip in fluid coupling-low to high loadings.

Size | Max. Operating kW rating at various motor speeds | |||

| 580 | 720 | 960 | 1450 |

8 | - | 0.29 | 0.69 | 2.36 |

9.25 | 0.31 | 0.6 | 1.42 | 4.88 |

10.5 | 0.59 | 1.13 | 2.68 | 9,21 |

11.5 | 0.9 | 1.83 | 4.35 | 14.01 |

12.75 | Jan-64 | 3.13 | 7.53 | 26.1 |

14.5 | 3 | 5.67 | 13.42 | 46.2 |

16.25 | 5.44 | 10.44 | 24.76 | 75 |

17.75 | 8.13 | 15.51 | 37.29 | 120 |

20 | 15.73 | 30.13 | 75 | 151 |

23 | 30 | 56.7 | 130 | 275 |

26 | 58.2 | 112 | 210 | 455 |

29 | 101 | 187 | 340 | 615 |

32 | 155 | 271 | 420 | 837 |

36 | 273 | 345,00 | 725 | - |

41 | 410 | 634 | 1000 | - |