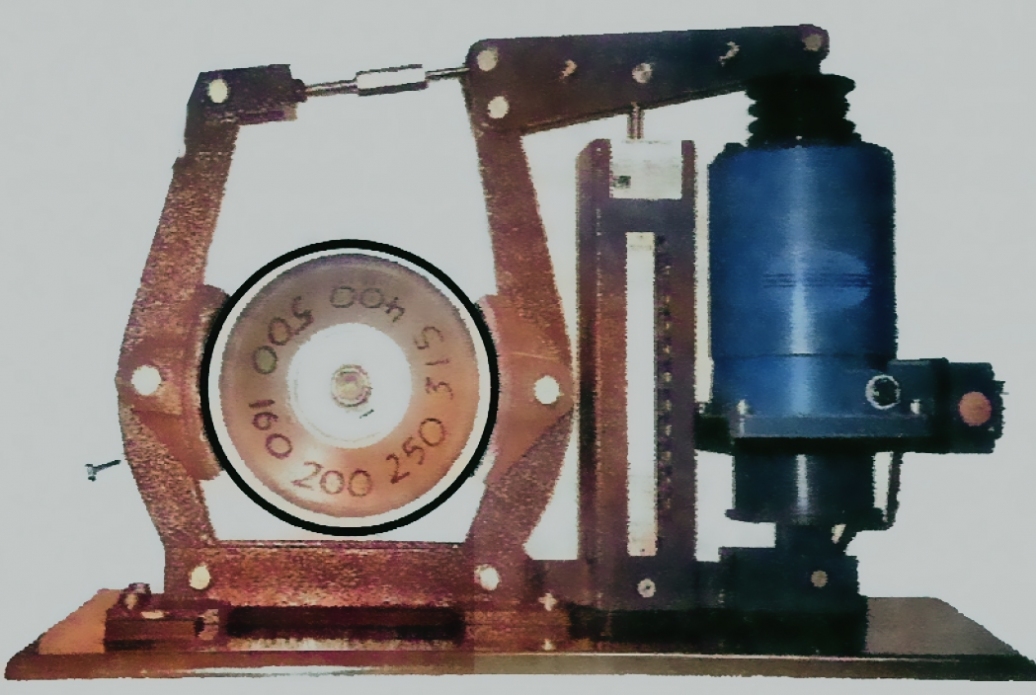

ELECTROMAGNETIC DRUM BRAKES

Electromagnetic Drum Brakes

Operating Principals:

- Spring Applied Braking .

- Releasing using Electromagnetic Actuator.

- Adjustable braking torque.

Construction:

-

The brake spring and brake lifter are laterally positioned.

-

Brake shoe lifter with single web construction.

-

Synchronous releasing mechanism.

Special Characteristics of the Brake-Type Binsi

-

All requirements of DIN 15435 are fulfilled, therefore assuring interchangeability.

-

High braking torque independent of the direction of rotation due to optimized lever geometry in connection with increased stiffness of the base plate and brake shoe lever.

-

Good lateral stability of the brake due to widened base of the brake shoe lever.

-

Synchronous releasing mechanism and brake shoe clamps guarantee a self-adjusting constant gap on the brake linings.

-

Increased safety due to tension bar structured with small stress concentration:

-

Encased tension bar threads enable an easy adjustment of the brake even under adverse operating conditions.

-

Bolts made of electroplated steel and box bearings increase their reliability of operation and life of the brake, all standard parts are galvanized.

-

The enclosed spring tube protects the brake spring against damage.

-

Simple adjustment of braking torque, easy-to-read torque scale.

-

Changing the brake shoes without dismantling the brake is possible.

-

According to DIN 15435, brake shoes are cast in light metal and boxed with steel bushes.

-

Brake linings, bonded type with a coefficient of friction of 0.4

-

Finish - Pacific blue.

Brake units fitted with standard silicon rectifier attachment. Units are available with built-in silicon rectifier suitable for direct AC mains connections of 380 or 525V three-phase. Brake operating coils are wound for 168 and 220V DC respectively.

Brake units with Force voltage silicon rectifier attachment. This rectifier unit is a special force voltage type, which for a limited period, supplies the brake with its nominal DC operating voltage.

This reduces the normal brake release time by 40%.

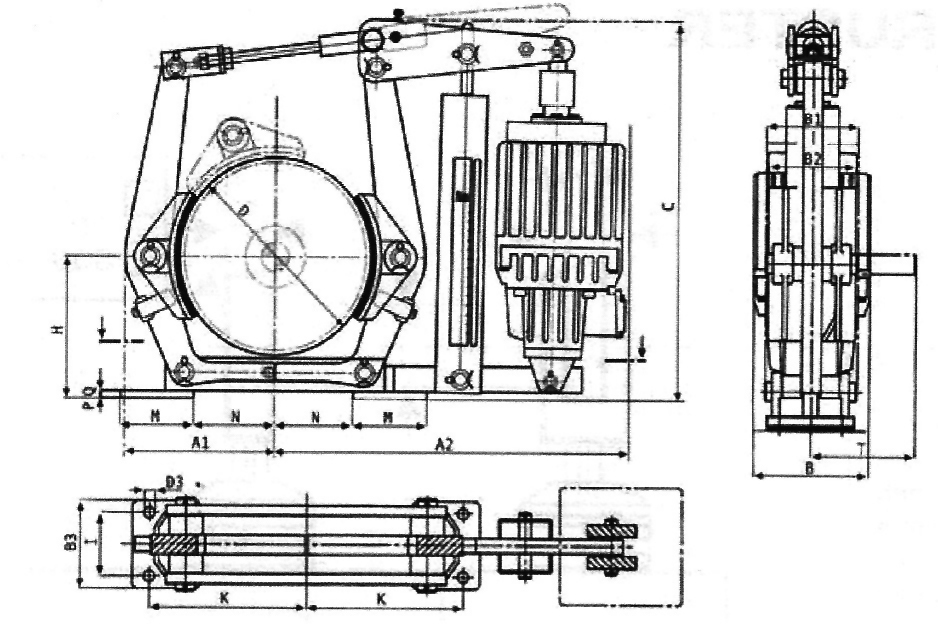

Brake Drum Specifications

All dimensions are in mm. Alterations are reserved without notice.

Dia | Binsi | Braking Torque | A1 Max | A2 Max | B Max | C Max | B1 | B2 | B3 | D3 | H | I | K | M | N | P | T | WEIGHT (kg) *Excluding actuator |

(D) | Nm | |||||||||||||||||

160 | 160-14 | 55-230 | 145 | 385 | 160 | 400 | 66 | 55 | 90 | 12 | 130 | 55 | 120 | 70 | 75 | 8 | 78 | 22 |

200 | 200-14 | 85-400 | 180 | 430 | 160 | 475 | 75 | 70 | 80 | 14 | 160 | 55 | 145 | 90 | 85 | 10 | 105 | 36 |

250 | 250-14 | 100-850 | 210 | 485 | 160 | 510 | 130 | 90 | 110 | 18 | 190 | 65 | 180 | 80 | 119 | 10 | 140 | 51 |

315 | 315-14 | 75-1050 | 260 | 625 | 160 | 620 | 165 | 110 | 127 | 18 | 230 | 80 | 220 | 100 | 140 | 10 | 151 | 74 |

315-216 | 90-1700 | 260 | 645 | 175 | 620 | 165 | 110 | 127 | 18 | 230 | 80 | 220 | 100 | 140 | 10 | 151 | 87 | |

400 | 400-14 | 100-1100 | 322 | 760 | 160 | 710 | 175 | 140 | 160 | 22 | 280 | 100 | 270 | 120 | 178 | 12 | 190 | 119 |

400-16 | 100-1800 | 322 | 770 | 180 | 710 | 175 | 140 | 160 | 22 | 280 | 100 | 270 | 120 | 178 | 12 | 190 | 130 | |

400-18 | 125-2750 | 322 | 780 | 200 | 710 | 175 | 140 | 160 | 22 | 280 | 100 | 270 | 120 | 178 | 12 | 190 | 139 | |

500 | 500-14 | 200-1400 | 395 | 845 | 200 | 787 | 220 | 184 | 190 | 22 | 340 | 130 | 325 | 150 | 205 | 16 | 235 | 177 |

500-16 | 200-2200 | 395 | 855 | 200 | 787 | 220 | 184 | 190 | 22 | 340 | 130 | 325 | 150 | 205 | 16 | 235 | 190 | |

500-18 | 200-3400 | 395 | 865 | 200 | 787 | 220 | 184 | 190 | 22 | 340 | 130 | 325 | 150 | 205 | 16 | 235 | 197 | |

500-20 | 200-5400 | 395 | 875 | 220 | 787 | 220 | 184 | 190 | 22 | 340 | 130 | 325 | 150 | 205 | 16 | 235 | 220 |

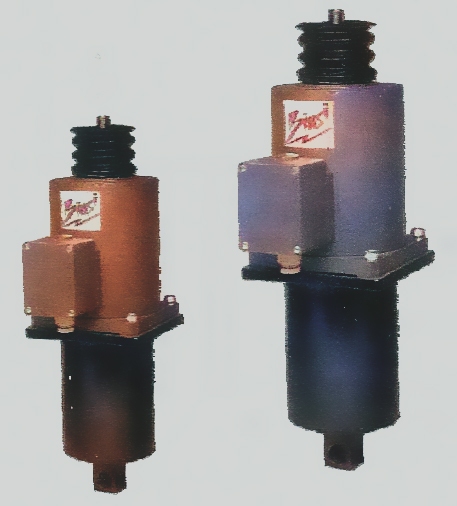

Actuator

Single acting Actuator Type: 41054...E with Mounting Flange & Terminal box

To replace existing hydraulic thrusters with Binzi Electro-Mechanical actuator, please download the Thruster Replacement Information below, fill in all existing dimensions, and e-mail it to sales@quesco.co.za

Size | Max Stroke | More Than 4 operations per second | 4 operations per second | ||||||||||

Force | Mag Stroke Time | Return Time | Input PowerForce | Mag | Return Strike Time | Time Input Power | |||||||

DC Switched | AC Switched |

| Type 41054 | DC Switched | AC Switched |

| Type 41504 | ||||||

S mm | F N | t1 ms | t2 ms | T2 ms | P20 W | P20 WA | f N | Ti ms | t2 ms | t2 ms | P20 W | P 20 WA |

|

14 | 50 | 250 | 600 | 180 | 500 | 160 | 215 | 300 | 500 | 160 | 425 | 260 | 375 |

16 | 60 | 340 | 650 | 210 |

| 235 |

| 440 | 550 | 190 |

| 380 |

|

18 | 65 | 500 | 770 | 260 |

| 270 |

| 650 | 630 | 230 |

| 450 |

|

20 | 70 | 750 | 850 | 320 |

| 360 |

| 1000 | 700 | 280 |

| 615 |

|